Bill’s Custom Fab, Inc. has provided custom design and fabrication services for creating structural steel components for a range of diverse applications since 1990. Over the years, the family-owned and operated business has worked with a wide variety of clientele, allowing the fabrication shop to expand its knowledge, experience, and expertise into many industries, ranging from construction and heavy-machine clients to residential and walk-in customers. In addition to custom design and fabrication, Bill’s Custom Fab’s services include steel erection, plasma burning, steel sales, shearing, bending, aluminum and stainless steel welding, and in-house and portable welding.

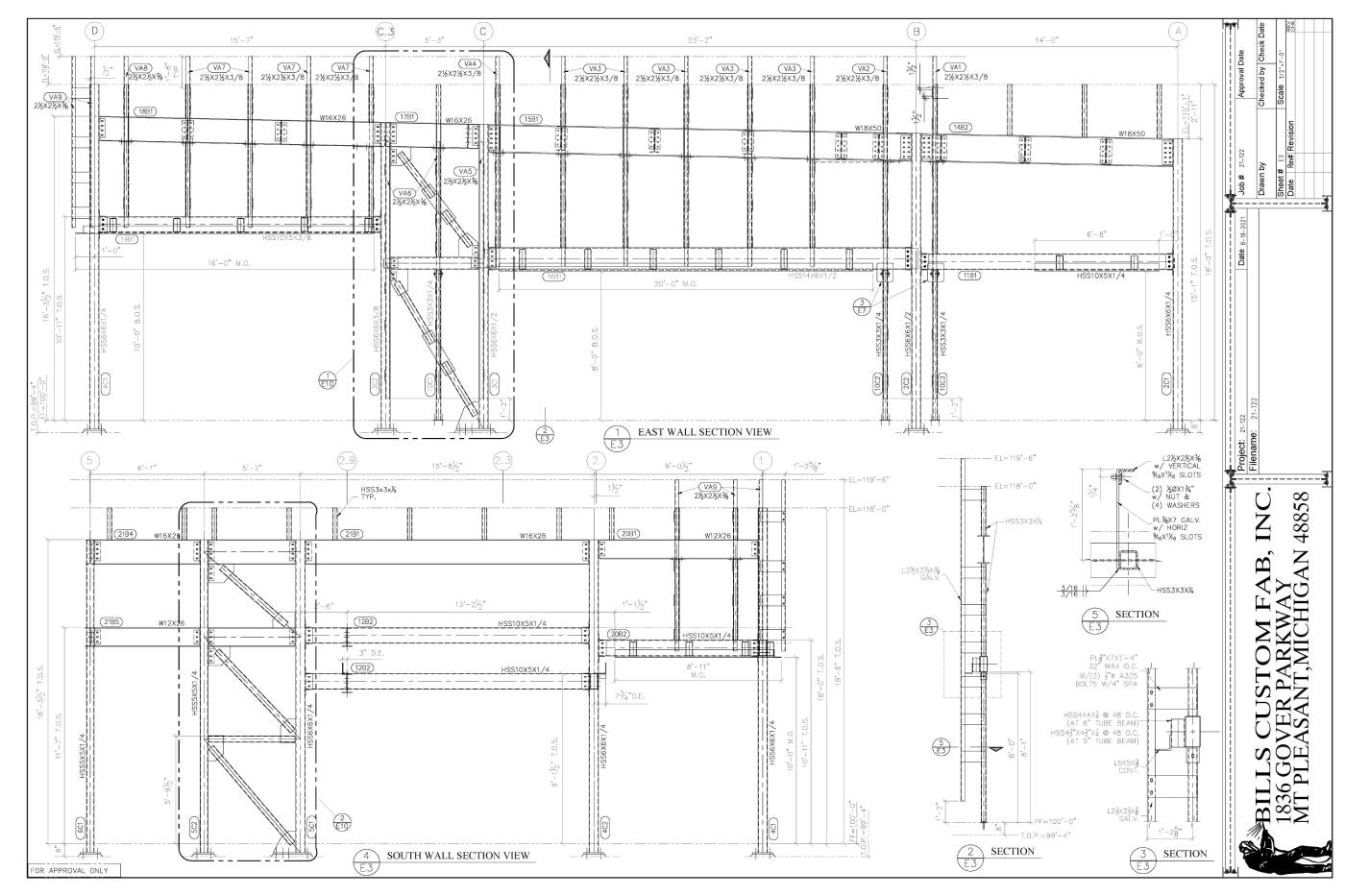

The firm uses 2D CAD for fabrication of structural steel—such as steel beams for construction, tubular steel for handrails, and steel channels for stair stringers. The management team at Bill’s Custom Fab, Inc. is committed to quality improvements. The company periodically re-evaluates its design and fabrication tools with an eye toward increasing efficiency, boosting productivity, or adding capabilities. Licensing changes with their former CAD provider-led Bill’s Custom Fab to re-evaluate its 2D design solution, according to Estimator David Yerks.