Some of the brightest minds in the oven and heat-treating industry—with hundreds of years of combined heat treat experience—came together in 2000 to form HeatTek, Inc. The company provides high-quality heat treatment equipment, superior customer service, and on-site support. With a commitment to research and development, HeatTek has grown to become a pioneer in the heat treatment industry, helping its manufacturing customers remain as profitable and efficient as possible.

Initially, the company exclusively used AutoCAD® 2D drawing software to create its oven, furnace, and heat treatment equipment designs. When HeatTek’s management decided to move to SOLIDWORKS® 3D design software in 2014, the goal was to satisfy customer demand for shorter lead times by increasing efficiency and throughput. However, the company discovered that it still needed a 2D design tool for handling simple layouts and schematics; accessing its legacy of AutoCAD designs and data; and supporting functions outside of engineering and design, according to Project Engineer II Mike Galligan.

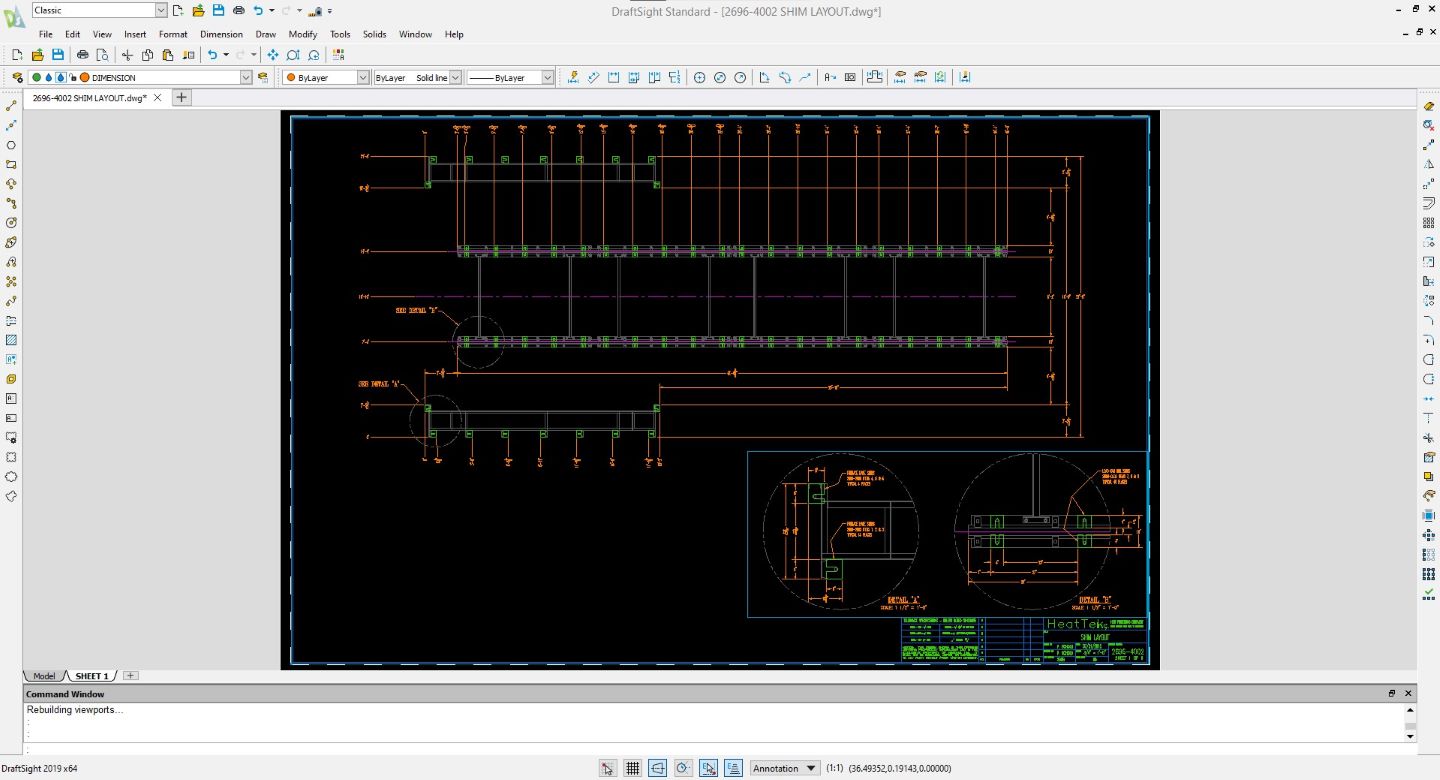

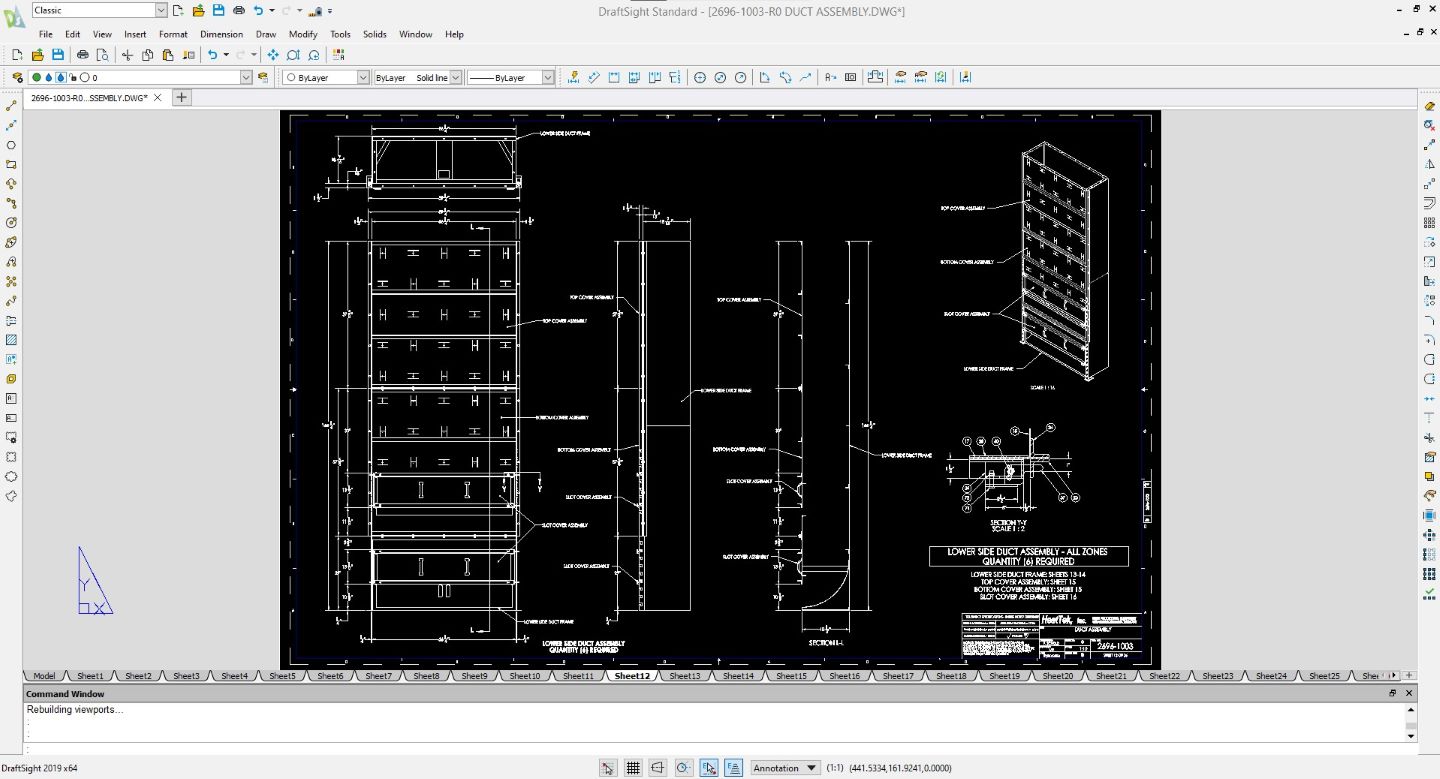

“Everyone we spoke with recommended SOLIDWORKS 3D design over Autodesk Inventor. However, we still needed an AutoCAD-compatible 2D solution for a couple reasons,” Galligan recalls. “There are other departments and personnel who don’t necessarily need a 3D CAD license but still need access to design information as we often review our legacy designs when beginning a similar project. Also, our fabricators need DWG files to manufacture components and assemblies. While we can create those in SOLIDWORKS, others often need to access them. We learned about DraftSight software from our SOLIDWORKS reseller and implemented it as part of our SOLIDWORKS transition.”

HeatTek purchased about 50 licenses of DraftSight Professional software to meet its 2D needs. “Our DraftSight Professional subscription costs significantly less than AutoCAD,” Galligan explains. “Plus, DraftSight is fully interoperable with SOLIDWORKS, allowing our employees to go back and forth between the two applications. DraftSight meets all our 2D needs with less cost, which is why we’ve purchased enough licenses to have 50 people use it at any one time.”